Our manufacturing technology

Advantages of using

list of advantages

Individual design

Quick commissioning

Water resistance

High level of strength

Chemical resistance

Long service life

Frost resistance, fire resistance

Aesthetic appearance, color choice

RulonBeton

RulonBeton

RulonBeton

FormaBeton

FormaBeton

FormaBeton

The semi-finished material  consists of reinforcement of basalt threads /roving

consists of reinforcement of basalt threads /roving  woven into a volumetric power frame

woven into a volumetric power frame  with specified strength characteristics.

with specified strength characteristics.

There is a specially created matrix (binder) between the force layers of reinforcement composite material is a semi-finished product consisting of mineral filling, special cement, a unique set of polymers and additives.

The lower or inner layer in the semi-finished material is made of polymer and does not allow moisture to flow out of the product during the closing of the dry matrix.

The upper or outer layer is made of woven material, which does not allow the dry matrix to spill out even if the material is mounted vertically or on the ceiling.

If one or more layers in a semi-finished material are made of wire, then a ForBeton is obtained, a product that allows you to create specified shapes, products, structures and maintain them until the strength is set by the main matrix.

The thickness of the semi-finished material is from 6 to 40 mm, the width is from 600 to 1800 mm, the length is limited by the weight of the roll, from 5 meters – 70 kg to 125 meters – 2000 kg.

The semi-finished material is manufactured in production, where it is given the specified strength and performance characteristics.

Depending on the operating requirements, finished products made of rolled concrete and ForBeton can perform load-bearing, barrier, covering, fire-retardant, decorative and other functions.

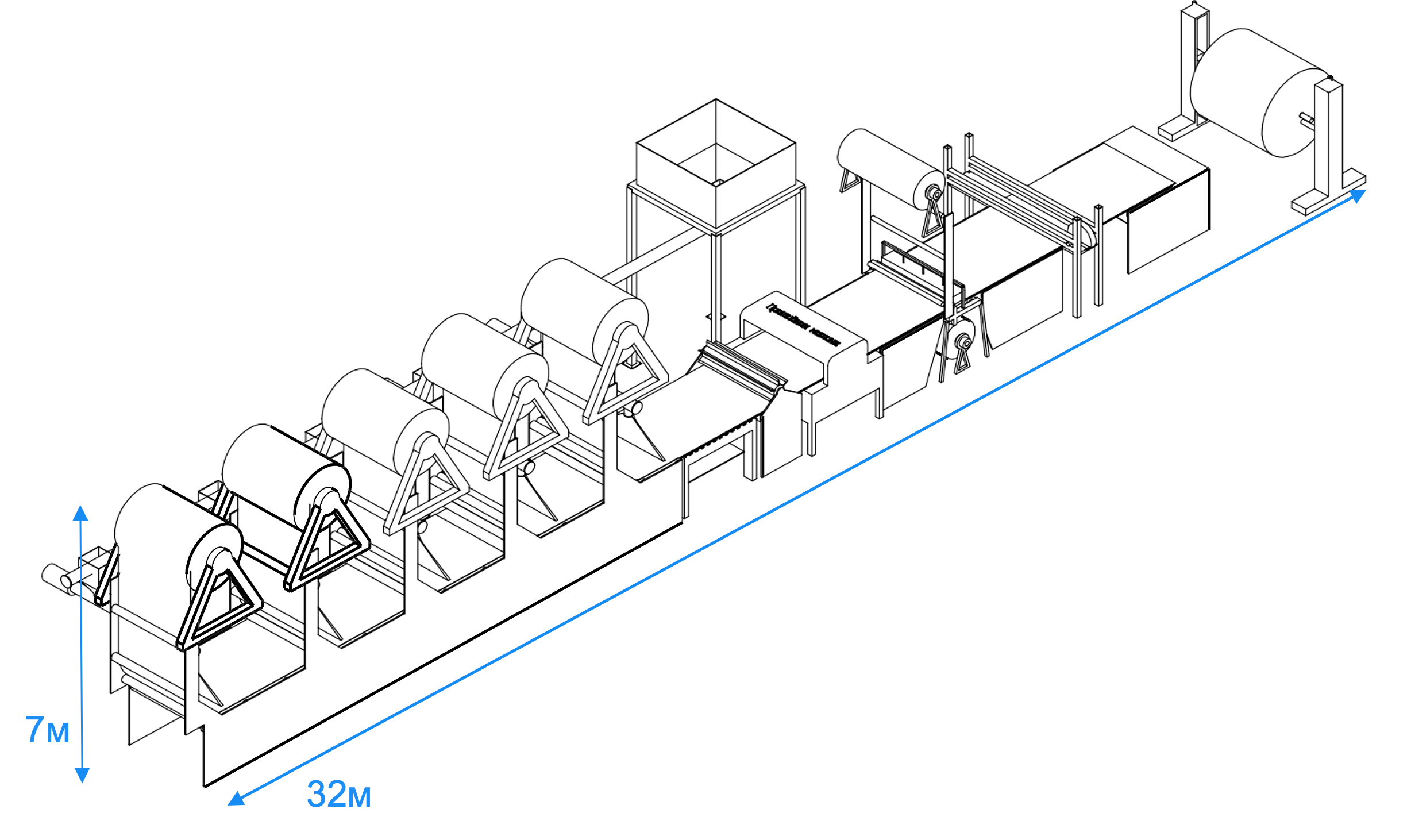

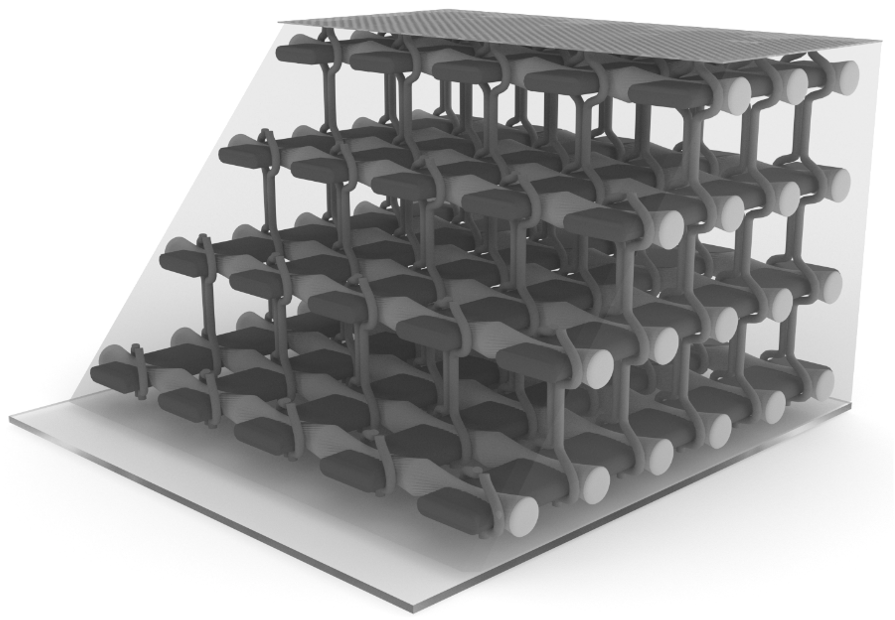

production line

production line

production line

production line

production line

Production line

The production process

Main feed

The main feed of the dry mixture

Layer dispensers

Dispensers of dry mix layers

Layer feed

Feeding of Basalt mesh layers

Main conveyor

Main Forming Conveyor

Waterproof layer

Installation of the application of a waterproof layer

Main machine

The main sewing machine

Finished products

Finished products at the exit

Comparison of the RulonBeton ®

with existing technologies

at a distance of 10 km from the object

What is required

2 mixers, 17 tons of ready-mixed concrete

Heavy mechanization work

Fixtures, formwork

Heavy mechanization work

Fixtures, formwork

5 rolls

of 550 kg

Type of concreting

Concrete M300

Horizontal / Inclined

RulonBeton®

Horizontal / Inclined

Thickness, mm

40 / 40

10 / 10

Weight, tons

17 / 17

2,8 / 2,8

Price for materials, ₽

21 000 / 21 000

120 000 / 120 000

Price per product, ₽

187 000 / 296 500

126 750 / 126 750

Savings with the same logistics, when using a RulonBeton®

32,22 % / 57,25 %

Production technology

The development and testing of the material was carried out on the basis of the laboratory of Wacker Chemie AG

Top layer

Water-permeable layer

Matrix

Dry cement-polymer matrix

Reinforcement

3D reinforcement of basalt threads

Bottom layer

Waterproof layer